Since 1990, Esatec France has been working for the printing & packaging industry. The company is a specialist in the design and manufacture of successful 360 degreewindow patching machine

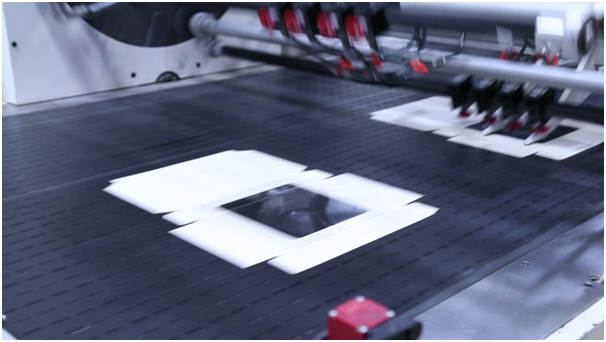

The DigiStar WPPP is a multi functional automatic window application systems unit which cuts film in line from roll and places pre-creased / die cut plastic windows onto finished carton blanks using a highly bespoke and electronic pre programmed management system, encompassing a very tactile pick and place movement process incorporating a cold glue stencil application unit, if required two windows can be placed in line in one operation.